Container Room Rain Gutter Roll Forming Machines

MEI SHUN Container Room Rain Gutter Roll Forming Machines Advantages

MEI SHUN factory use the raw materials with excellent quality to ensure stable well operation of the machines.

MEI SHUN factory has professional processing of the design, develop and manufacture, also have proven machining technique. Each machine with strict quality control.

Our container room gutter forming machine consists of Decoiler - Hydraulic Pre Punching Device - Main Roll Forming Mill - Post Cutter - Hydraulic Station - FLC Control Cabinet.

- Meishun

- Xiamen

- 30-50 days

- 100 sets

- Information

Container Room Rain Gutter Roll Forming Machines

| Equipment Parameters | |

| Equipment Name: | Container Room Rain Gutter Roll Forming Machine |

| Forming Steps: | 16 groups roller |

| Equipment Components: | Decoiler - Hydraulic Pre Punching Device - Main Roll Forming Mill - Post Cutter - Hydraulic Station - FLC Control Cabinet |

| Equipment Size (L x W x H) | 9.8m x 1.5m x 1.2m |

| Main Motor Power | 7.5KW |

| Hydraulic Motor Power | 3KW |

| Equipment Total Weight | Approx. 7 tons |

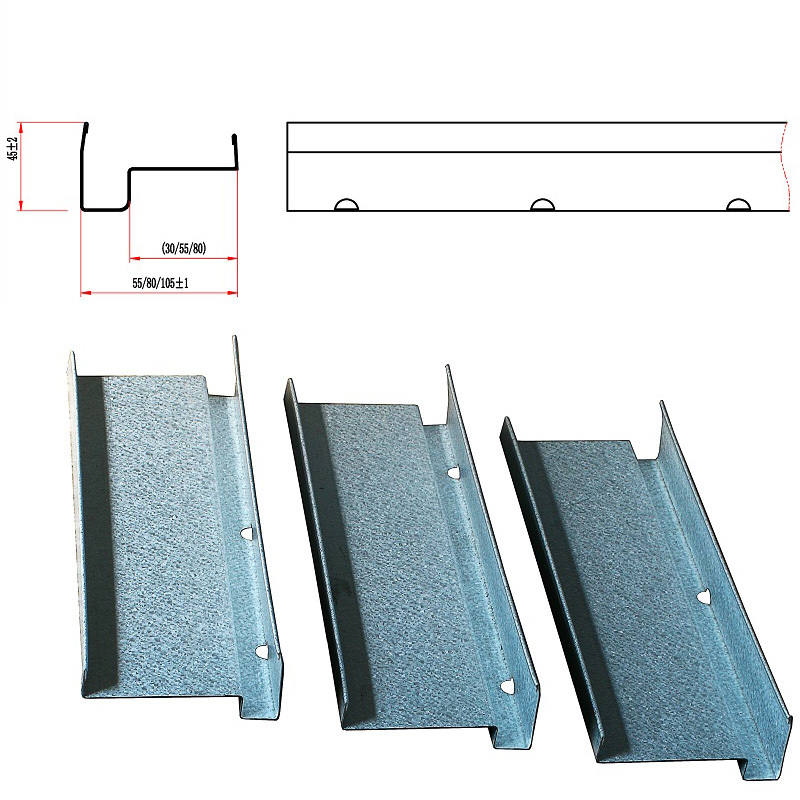

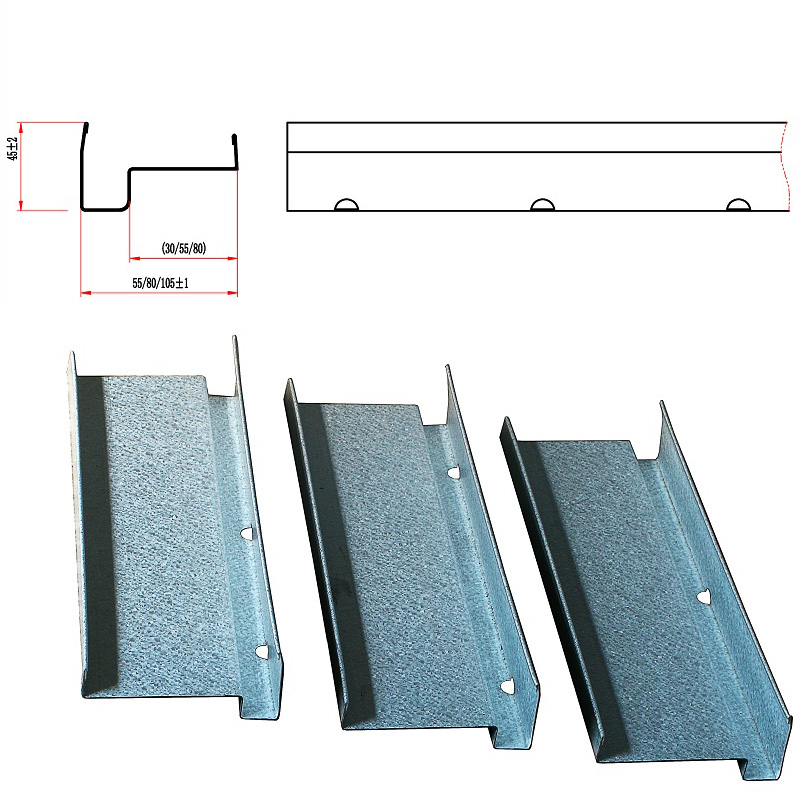

The rain gutter forming machine is a downpipe product that collects rainwater from the roof. Then the downpipe produced by the downpipe machine usually flows rainwater into the underground pipe. This process is only for water treatment. It can be seen that the downpipe work is very simple. Our downpipe forming machine is mainly composed of uncoiler, forming system, cutting equipment, protective device, hydraulic system, control system and workbench. It can make the downpipe form a curve to meet the requirements of the actual project.

Welcome sending your profile drawing & parameters, we will do customized. Cost effective and high performing roll forming machine as you want.