Rack Upright Roll Forming Machine

MEI SHUN Rack Upright Roll Forming Machine advantage:

1.CEO Mr. Wang is a professinal Engineer has very rich experience in the cold roll forming equipment design and producing. He's the Member of Working Group of China Cold Rolling Forming Equipment (SACTC220WG4). It mean Mei shun factory could give you better technician services.

2.The structural parts are optimized by computer finite element analysis to ensure that the structural parts are firm and durable. The hydraulic system is well synchronized with the transmission system.

3.The line is adopting the comprehensive functions of computer integrated control technology, using computer man-machine interface, under the condition that the different parts of raw materials and production are all ready, input function of the production line running the required parameters and plate cutting length, it can automatic make production.

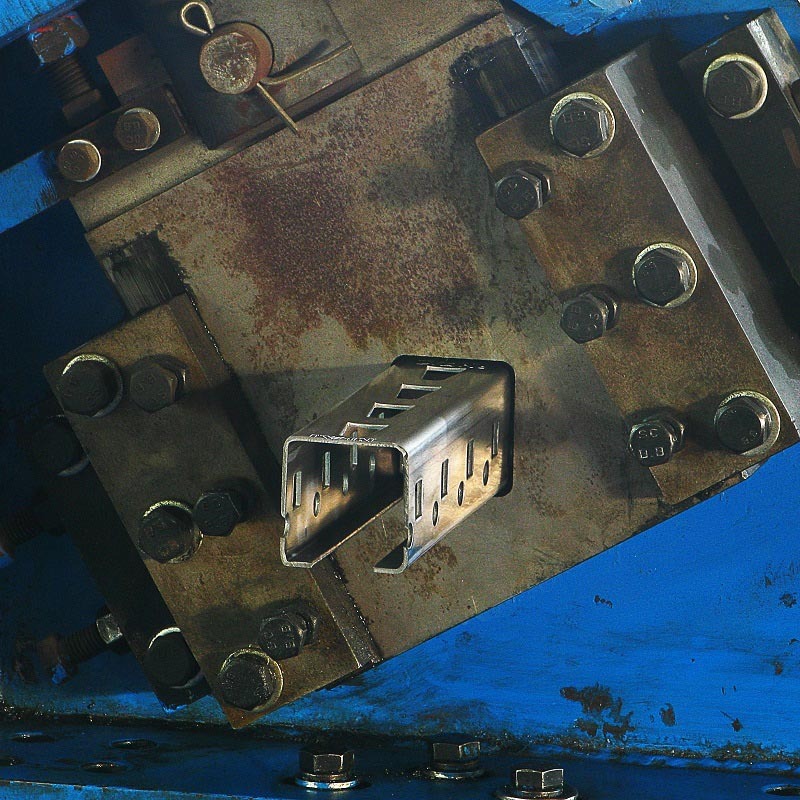

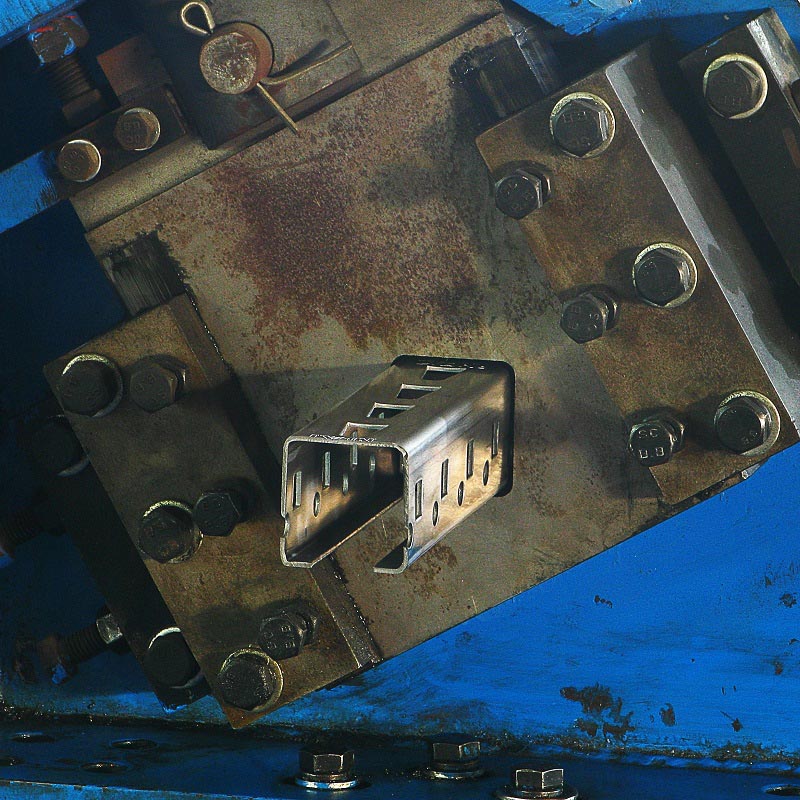

Our racking former machine is to produce all kinds of racking to meet the steel structure market.

After the equipment is arrived to the buyer’s factory, the buyer will install and run the equipment. And if required by the buyer, the seller will help the buyer to install and run the equipment. The buyer offers the transportation, communication and accommodation inside the buyer’s country for engineer of seller. And the buyer bears the engineer’s salary and round trip air tickets of the seller. The engineer’s salary is USD100 / day/person.

- Meishun

- Xiamen

- 30-50 days

- 100 sets

- Information

Rack Upright Roll Forming Machine

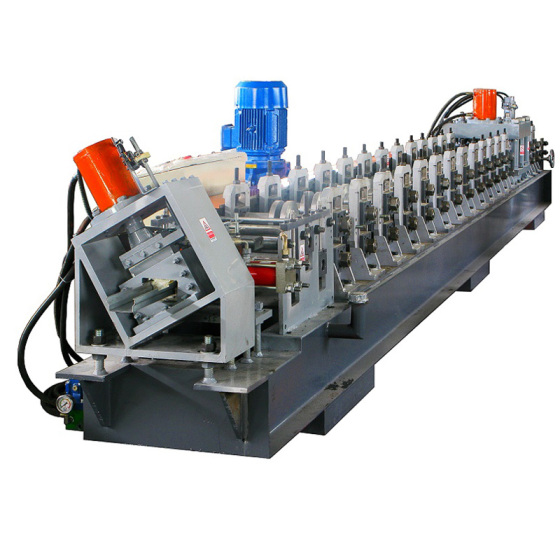

| Equipment Parameters | |

| Equipment Name: | U44.5*46 Rack Upright Roll Forming Machine |

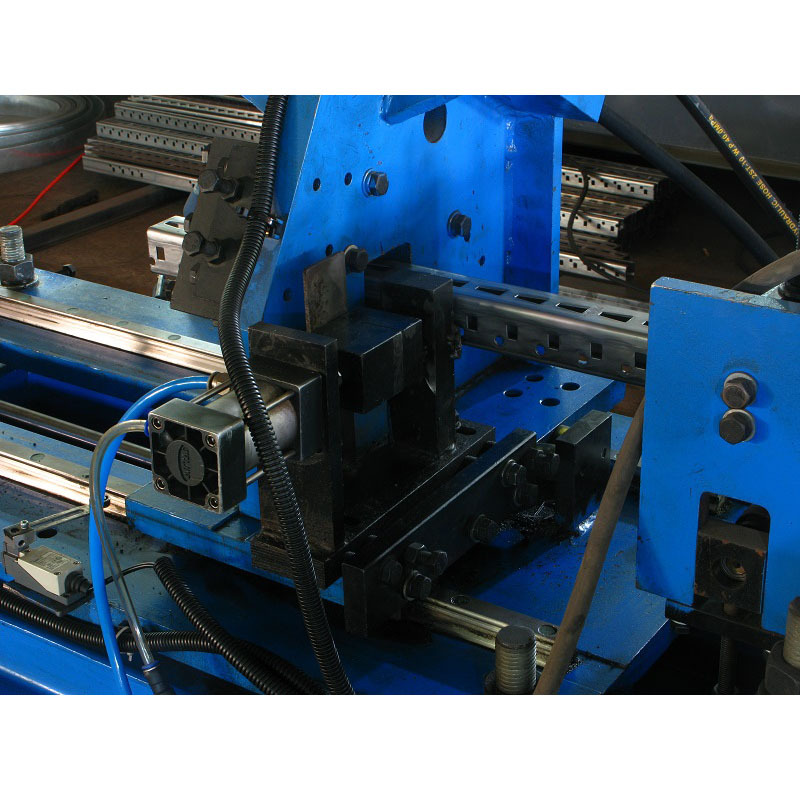

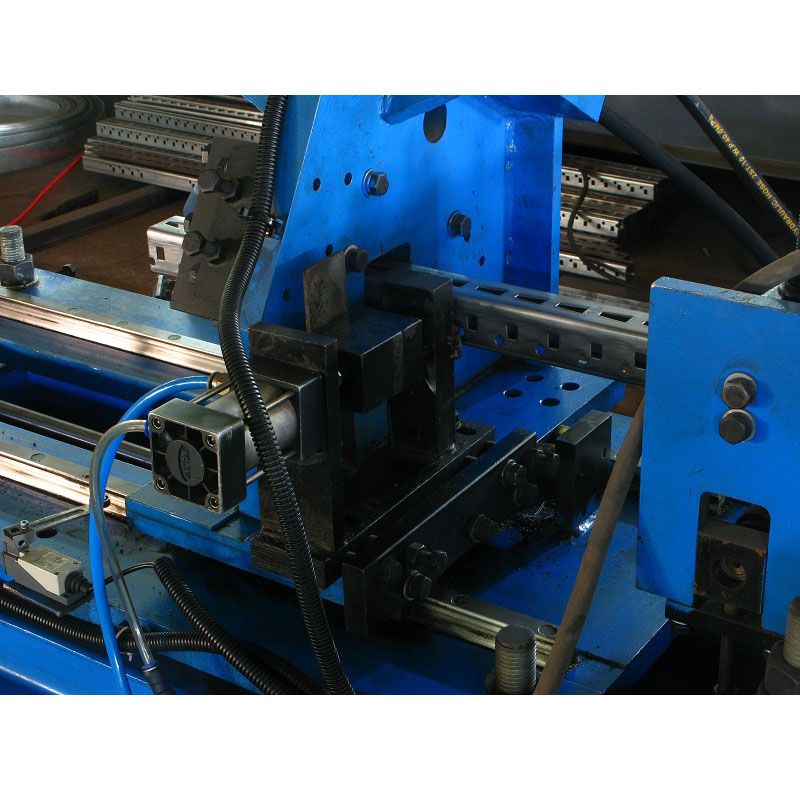

| Forming Steps: | 24 groups roller |

| Equipment Components: | Decoiler - Servo Driving Device - Hydraulic Pre Punching - Main Roll Forming Mill - Post Cutter - Hydraulic Station - FLC Control Cabinet |

| Equipment Size (L x W x H) | 20.0m x 1.5m x 1.2m |

| Main Motor Power | 11KW |

| Hydraulic Motor Power | 4KW |

| Equipment Total Weight | Approx. 12 tons |

Provide reliable machines in a wide range of industries, construction and other fields. We will continue to research, develop and produce high-performance, energy-saving, compact and environment-friendly roll forming machines to better adapt to environmental and social development and contribute to your production.

Our machine's warranty period is 12 months, if the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.