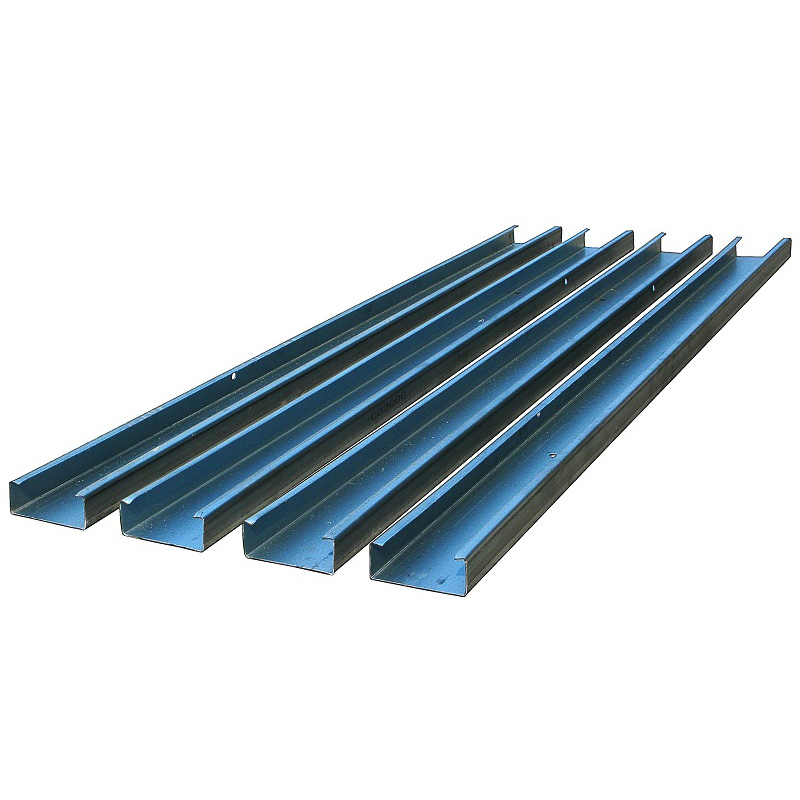

Steel C Profile Roll Forming Machines

MEI SHUN Steel C Profile Roll Forming Machine consists of Decoiler - Main Roll Forming Mill - Post Cutter - Hydraulic Station - FLC Control Cabinet.

Our roll forming machine parts use World classic brand, like TAIDA (PLC). WEILUN (Touch screen). OMRON (Frequency converter and the encoder). Schneider (Electrical components) are our work parners. By the integration of innovation and energy-saving technology, it realize more efficient, reliable, safe and lasting operation.

Our C Profile Roll Forming Machines production capacity 200 sets per year.

- Meishun

- Xiamen

- 30-50 days

- 100 sets

- Information

Steel C Profile Roll Forming Machines

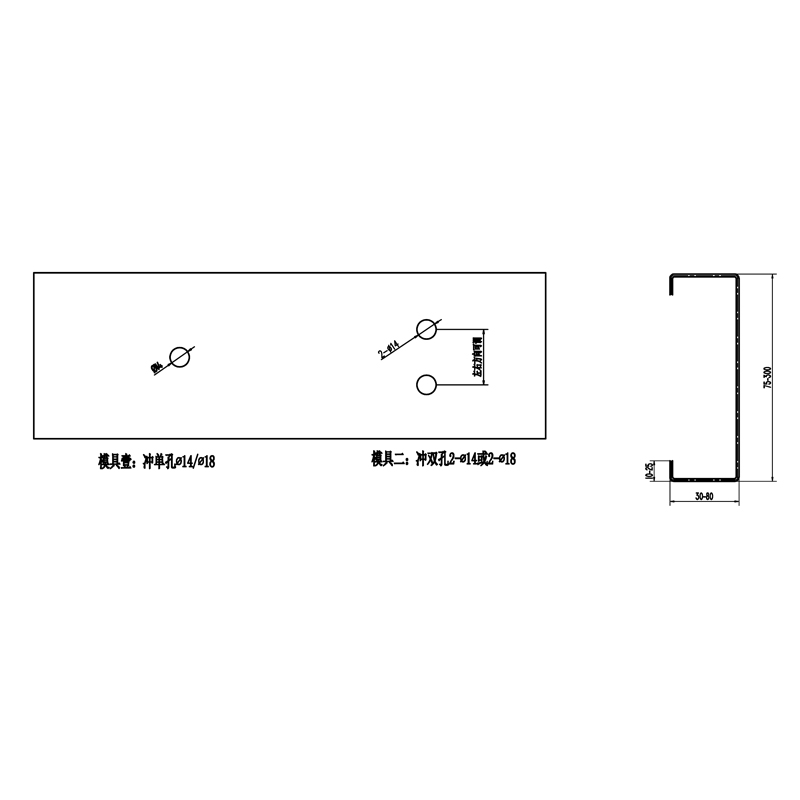

| Equipment Parameters | |

| Equipment Name: | C Shape Steel Profile Roll Forming Machine |

| Forming Steps: | 15 groups roller |

| Equipment Components: | Decoiler - Main Roll Forming Mill - Post Cutter - Hydraulic Station - FLC Control Cabinet |

| Equipment Size (L x W x H) | 18m x 1.5m x 1.2m |

| Main Motor Power | 18.5KW |

| Hydraulic Motor Power | 4KW |

| Equipment Total Weight | Approx. 10 tons |

| Blank Material Type | Galvanized Steel, Cold Roll Steel, Hot Roll Steel |

| Material Thickness | 1.0-3.0mm |

Our main engineers with 30 years' experience in design, R&D and production. They are understanding customers' different requirements, and satisfy well of customers" all over the world.

Please feel free contact us and sending your profile drawing & parameters. Our cost effective and high performing roll forming machine will satisfy well your requirement.

Most of our metal roll forming machines are designed and produced according to our customers specifications, with top brand components. Our machine's warranty period is 12 months