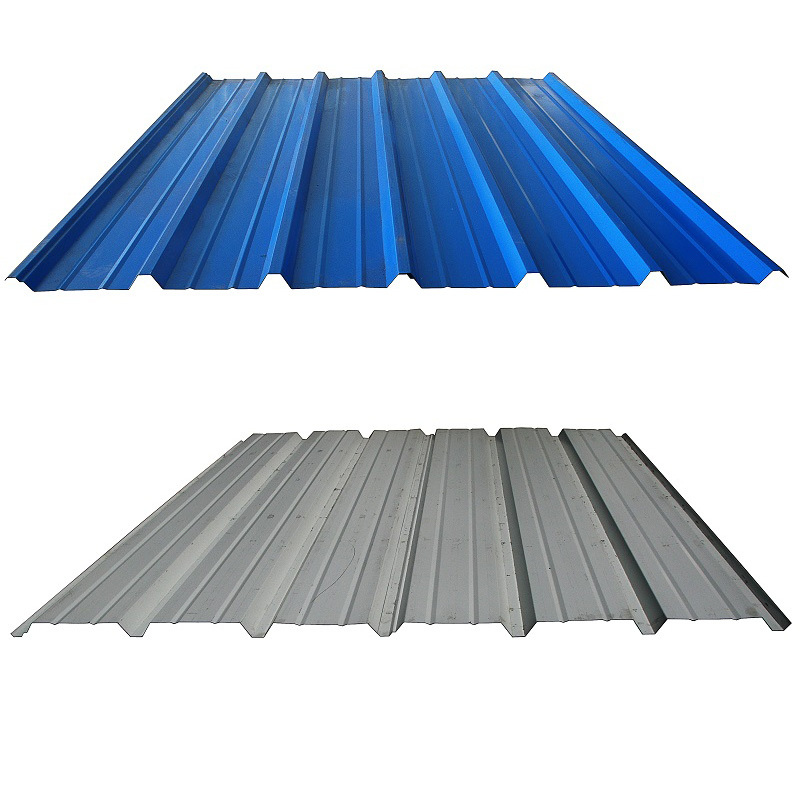

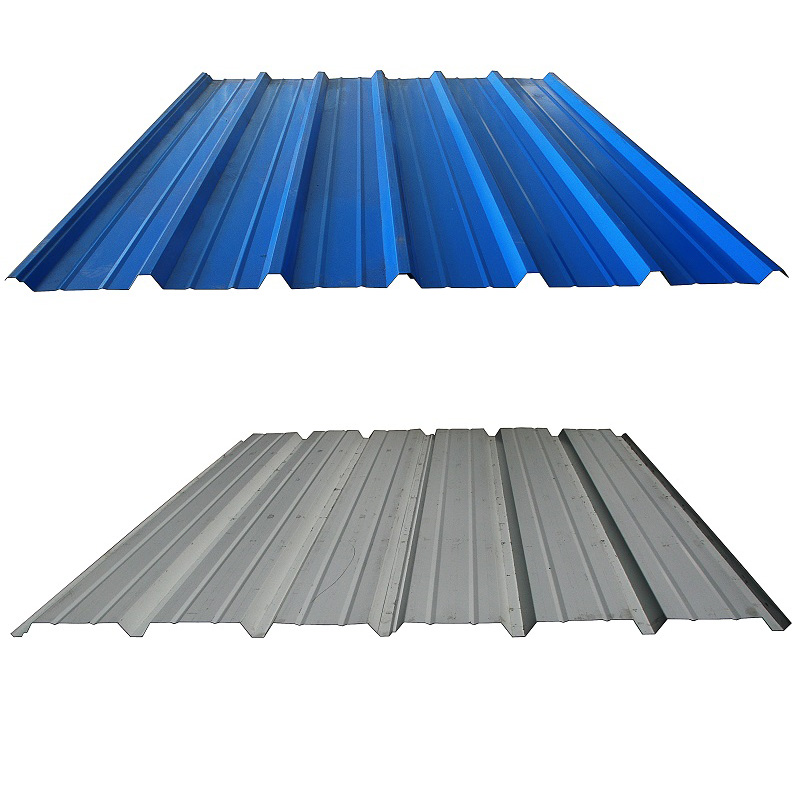

Pierce Fixed Roof Cladding Roll Forming Machine

MEI SHUN Pierce Fixed Roof Cladding Roll Forming Machine consists of Decoiler, Main Roll Forming Mill, Post Cutter, Hydraulic Station, FLC Control Cabinet, Exit Rack. The roofing sheet roll forming mill is with 24 steps rollers to roll form the sheet. This roll forming machine weights approx. 9 tons.

Meishun Machinery is specialized in design and manufactuer various kind of profiles roll forming machines, metal processing production lines, etc. Just send us your profile drawing at any time.

- Meishun

- Xiamen

- 30-50 days

- 100 sets

- Information

Pierce Fixed Roof Cladding Roll Forming Machine

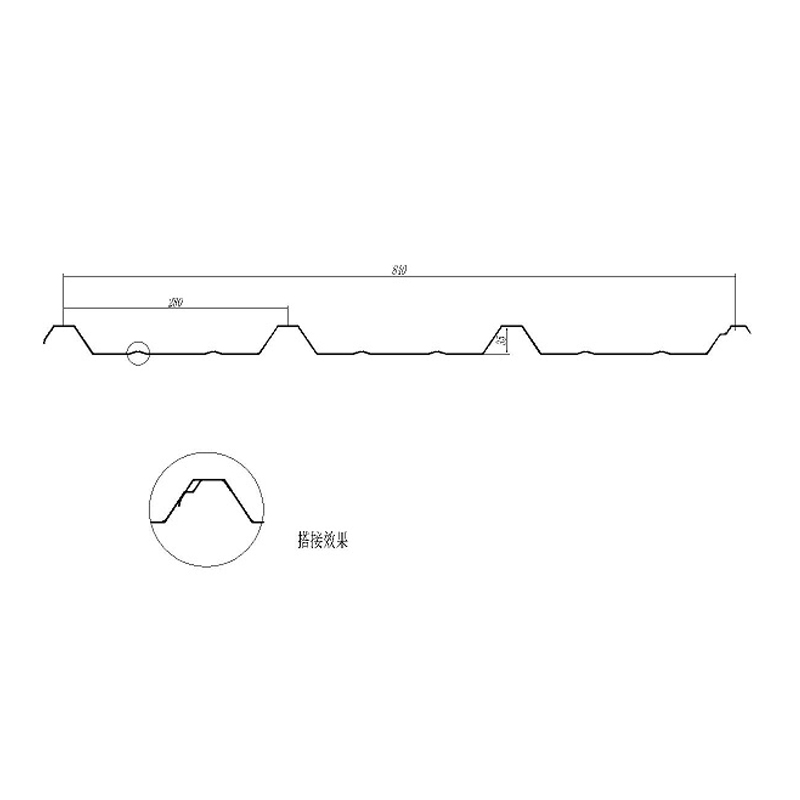

| Equipment Parameters | |

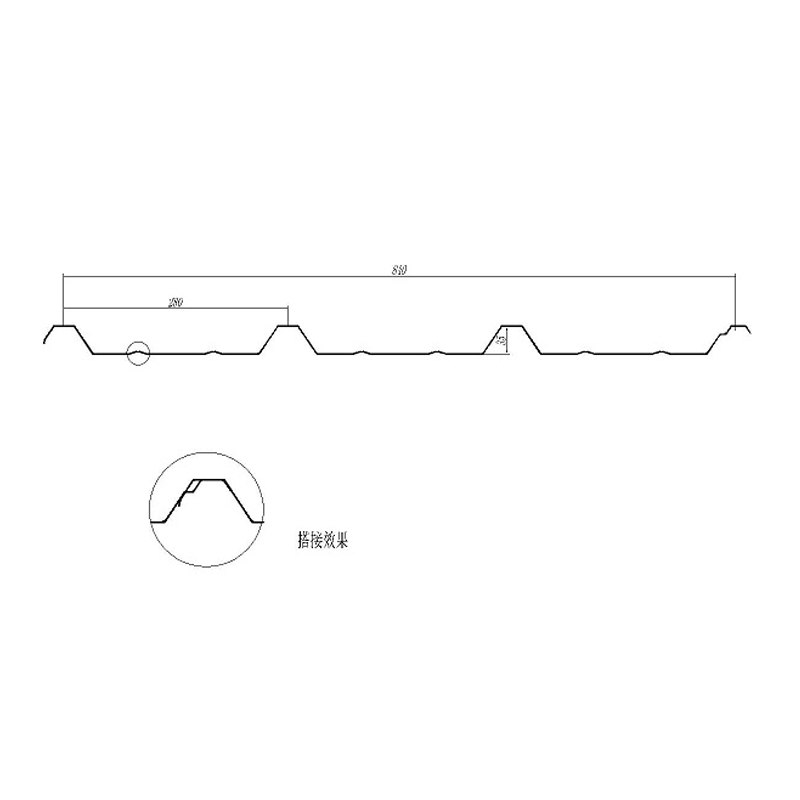

| Equipment Name: | MS35-280-840 Pierce Fixed Roof Cladding Roll Forming Machine |

| Forming Steps: | 24 groups roller |

| Equipment Components: | Decoiler - Main Roll Forming Mill - Post Cutter - Hydraulic Station - FLC Control Cabinet - Exit Rack |

| Equipment Size (L x W x H) | 11.5m x 1.5m x 1.2m |

| Main Motor Power | 11KW |

| Hydraulic Motor Power | 3KW |

| Equipment Total Weight | Approx. 9 tons |

| Material Width | 1200mm |

MEI SHUN roll forming machine works high efficiency. One person can easily operate machine. The machine production speed can be set as customer’s requirement.

We have our own professional processing of the design, develop and manufacture, also have proven machining technique. Each machine with strict quality control.

Through the integration of innovation and energy-saving technology, more efficient, reliable, safe and lasting operation can be realized.

After the equipment reaching buyer’s factory, the buyer will install and run the equipment. And if buyer have requirement, the seller will help the buyer to install and run the equipment. The buyer offers the transportation, communication and accommodation inside the buyer’s country for engineer of seller. And the buyer bears the engineer’s salary and round-trip air tickets of the seller.