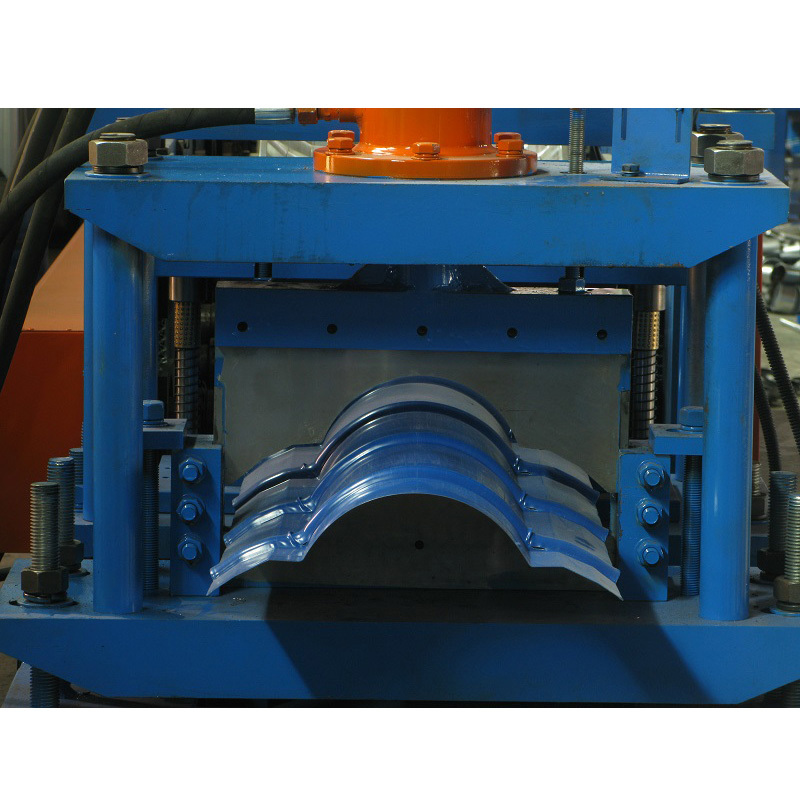

Roof Ridge Cap Roll Forming Machine

Advantages of MEI SHUN Metal Roof Ridge Cap Roll Forming Machine

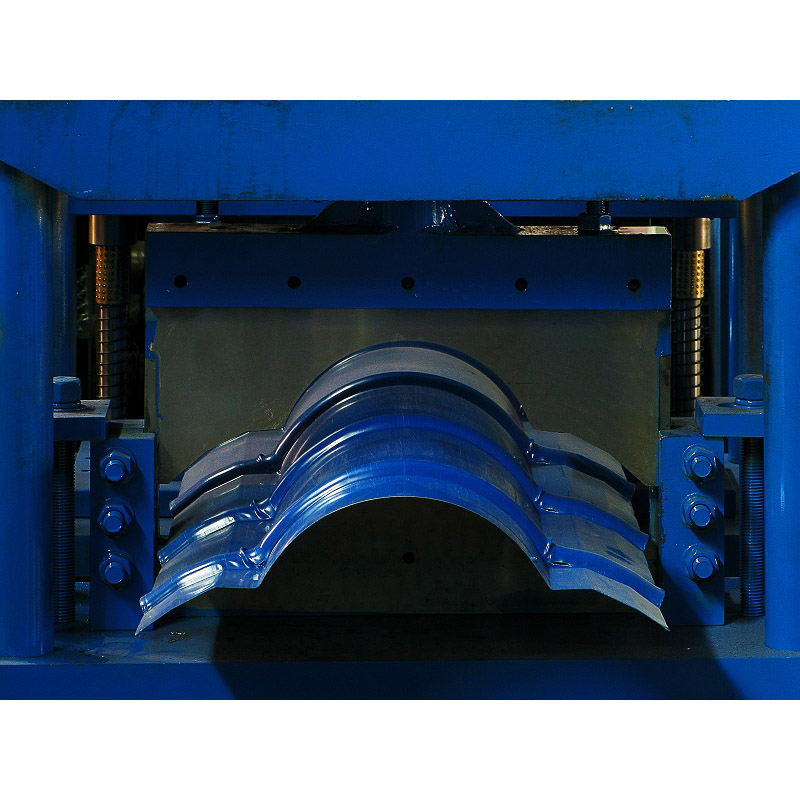

Roofing ridge roll forming machine is used to make ridge cap suitable for steel roofing. Except this, we could produce other types of roofing sheet roll forming machine, like glazed tile forming machine.

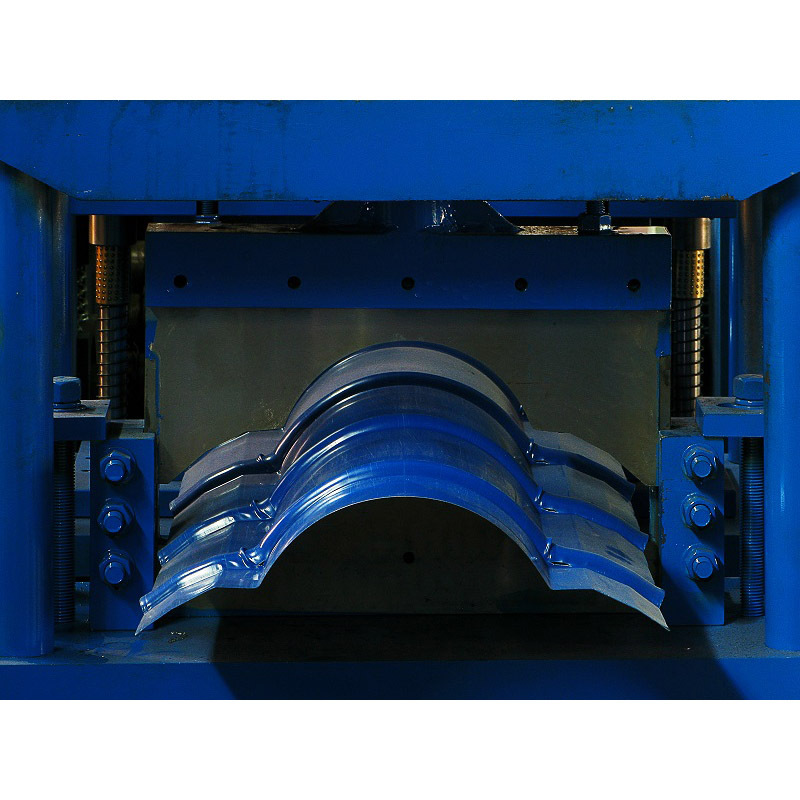

The structural parts are optimized by computer finite element analysis to ensure that the structural parts are firm and durable. The hydraulic system is well synchronized with the transmission system.

- Meishun

- Xiamen

- 30-50 days

- 100 sets

- Information

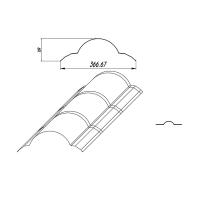

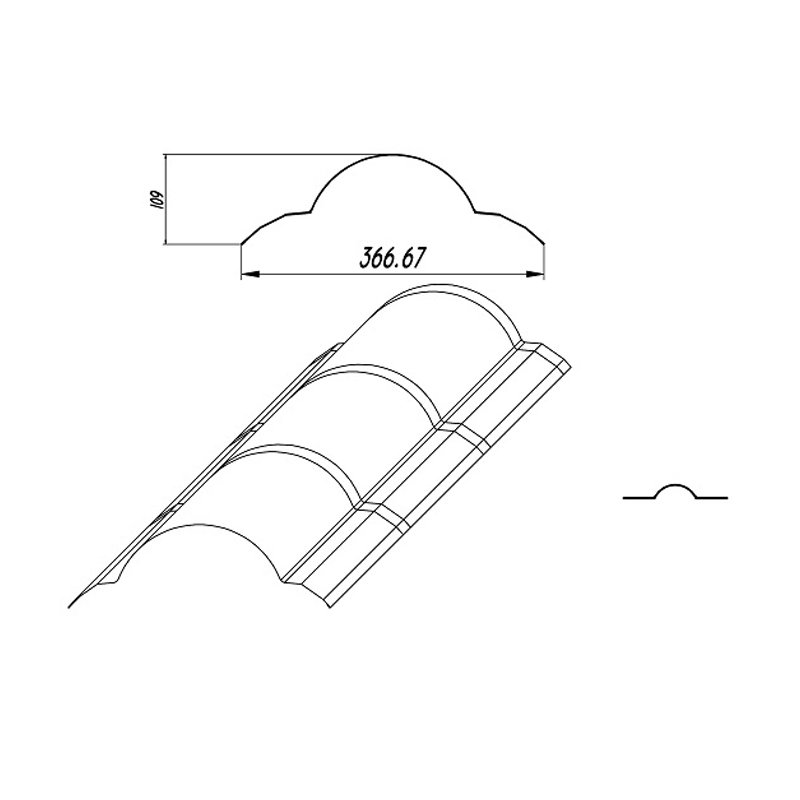

Metal Roof Ridge Cap Roll Forming Machine

| Equipment Parameters | |

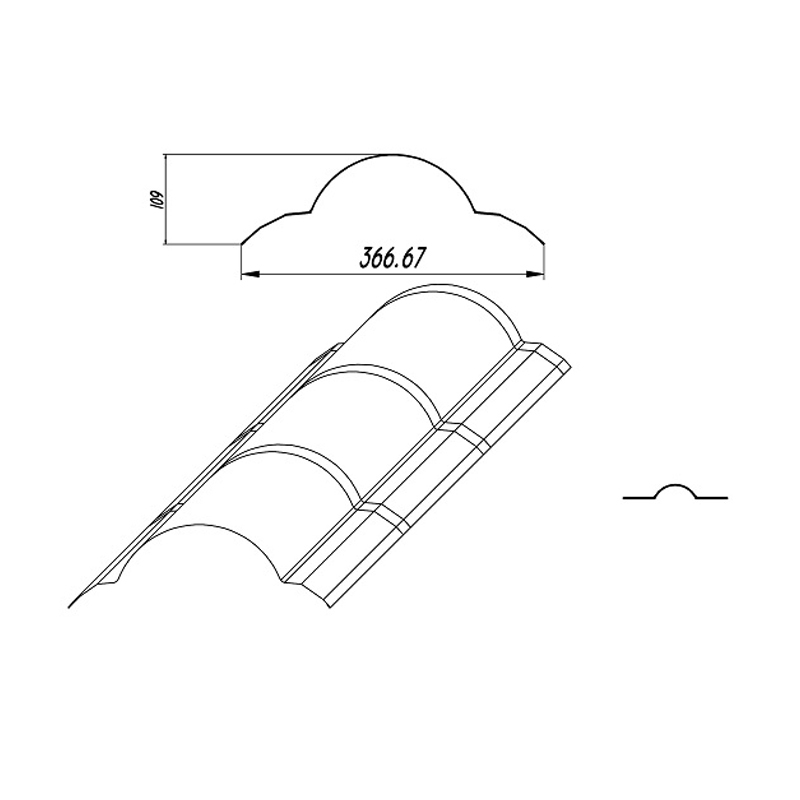

| Equipment Name: | MS109-366 Ridge Cap Roll Forming Machine |

| Forming Steps: | 14 groups roller |

| Equipment Components: | Decoiler - Manual Shear - Main Roll Forming Mill - Post Cutter - Hydraulic Station - FLC Control Cabinet - Exiting Rack |

| Equipment Size (L x W x H) | 6.0m x 1.5m x 1.2m |

| Main Motor Power | 5.5KW |

| Hydraulic Motor Power | 4KW |

| Equipment Total Weight | Approx. 5 tons |

| Material Width | 450mm |

Our main engineers with 30 years’ experience in design, R&D and production. They are understanding customers’ different requirements, and satisfy well of customers’ all over the world.

We are specialized in producing different types of automatic cold roll forming machines, such as roofing tile line, Light keel roll forming machine, shutter and door frame roll forming machine, rain gutter and downpipe forming line and HVAC Fire Damper Frame and Blade roll forming line.

Please feel free contact us and sending your profile drawing & parameters. Our cost effective and high performing roll forming machine will satisfy well your requirement.