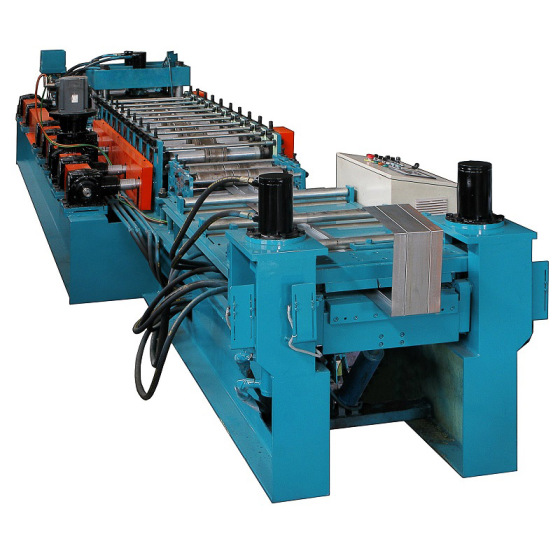

Fire Damper Leaf Spring Roll Forming Machine

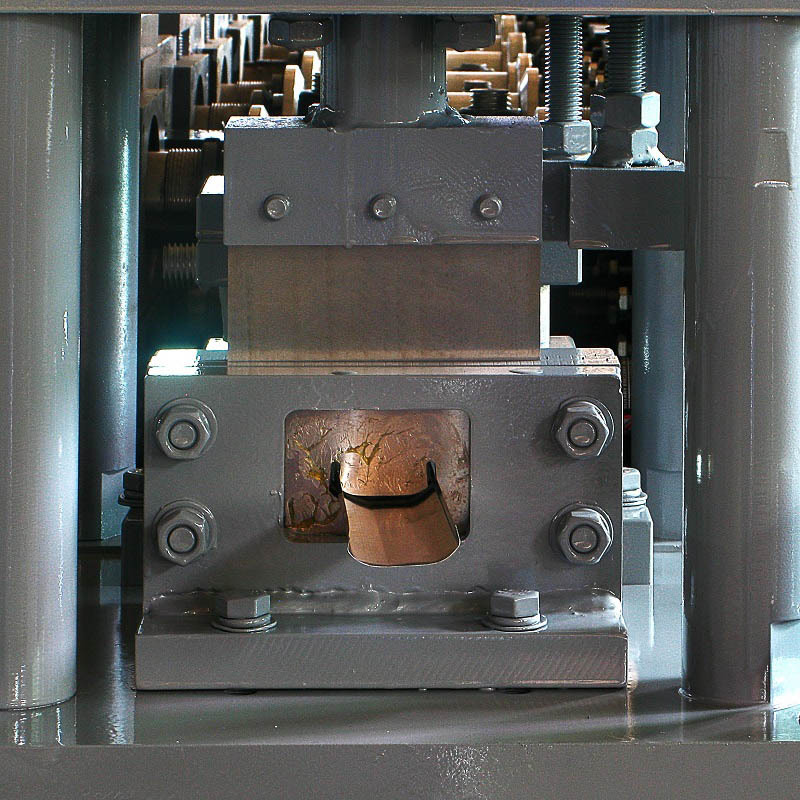

MS Fire Damper Leaf Spring Forming Machine is mainly composed of manual decoiler, roll forming machine, cutting & punching tools, electrical control system and hydraulic control system, widely used for the mass production of fire damper leaf spring. It is one of the important production line equipment for fire damper manufacture, with the advantage of high efficiency and precision, and stable performance.

We design and produce superior performance roll forming machine for fire damper frame, fire damper blade too.

High production precision and convenient operation: advanced PLC and touch screen control system are adopted. The machine has long service life and reasonable structure.

- Meishun

- Xiamen

- 30-50 days

- 100 sets/annual

- Information

Fire Damper Leaf Spring Roll Forming Machine

Fire Damper Leaf Spring Forming Machine is mainly composed of Decoiler, Main Roll Forming Mill, Punching Device, Post Cutter, Hydraulic Station, FLC Control Cabinet, Final Product Rack. It's widely used for the mass production of fire damper leaf spring. It is one of the important production line equipment for fire damper manufacture, with the advantage of high efficiency and precision, and stable performance.

| Equipment Parameters | |

| Equipment Name: | Fire Damper Leaf Spring Roll Forming Machine |

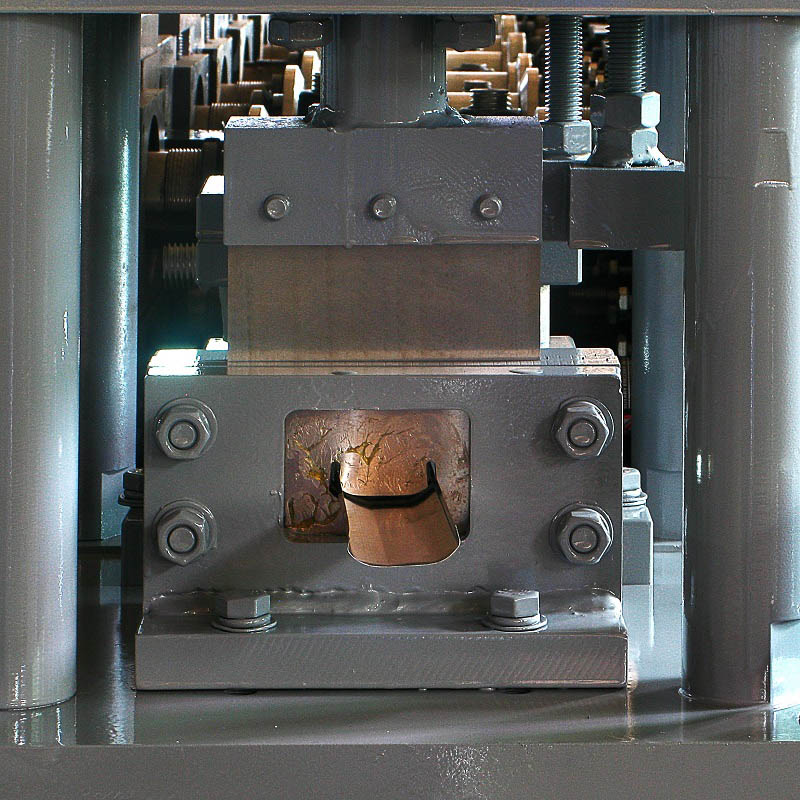

| Forming Steps: | 12 groups roller |

| Equipment Components: | Decoiler - Main Roll Forming Mill - Punching Device - Post Cutter - Hydraulic Station - FLC Control Cabinet - Final Product Rack |

| Equipment Size (L x W x H) | 4.5m x 1.0m x 1.2m |

| Main Motor Power | 3KW |

| Hydraulic Motor Power | 3KW |

| Equipment Total Weight | Approx. 3 tons |

| Feeding Material Width | 1000/1219mm |

Our roll forming machines are Fast running speed and wide application range. Easy maintenance.

High production precision and convenient operation: advanced PLC and touch screen control system are adopted.

The machine has long service life and reasonable structure.

Superior performance. Energy saving and environmental protection.

The transmission structure receives orders. Smooth operation.

Measurement: high performance servo control system is adopted to ensure production accuracy.

The structural parts are optimized by computer finite element analysis to ensure that the structural parts are firm and durable. The hydraulic system is well synchronized with the transmission system.

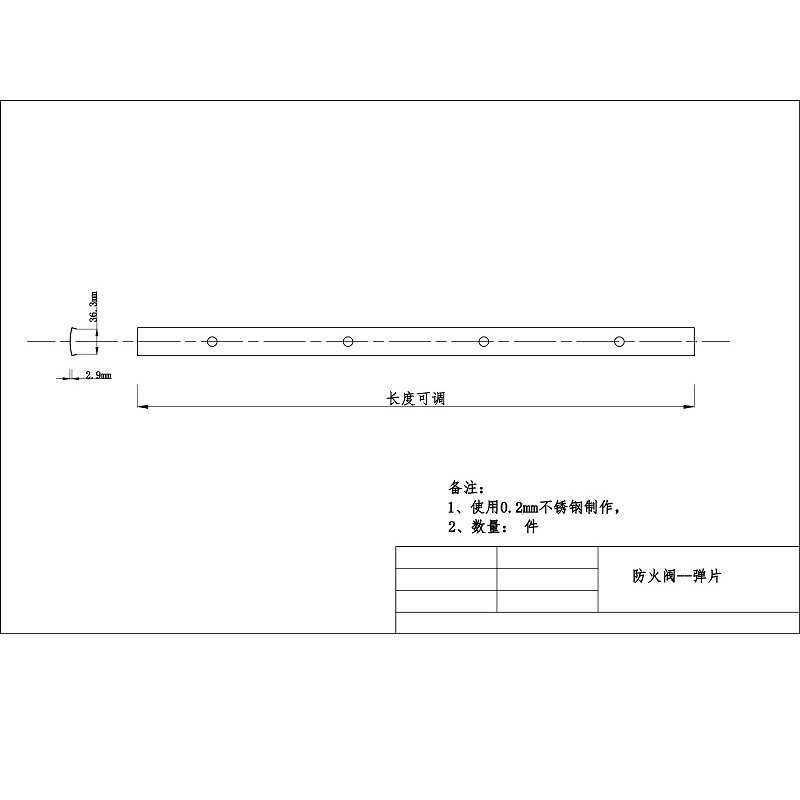

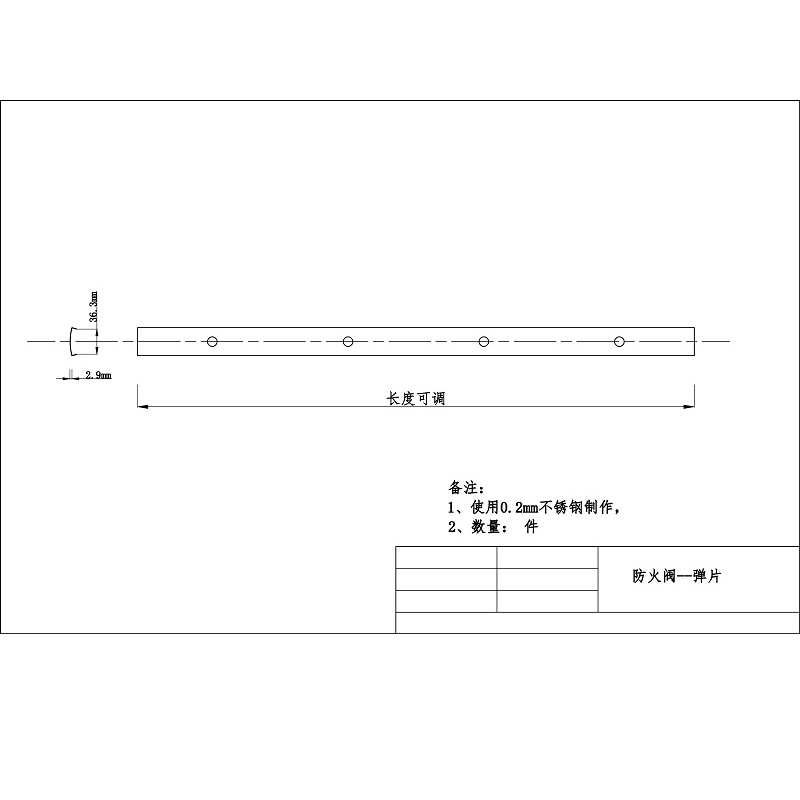

Welcome sending your profile drawing & parameters, we will do customized cost effective and high performing roll forming machine as you want.