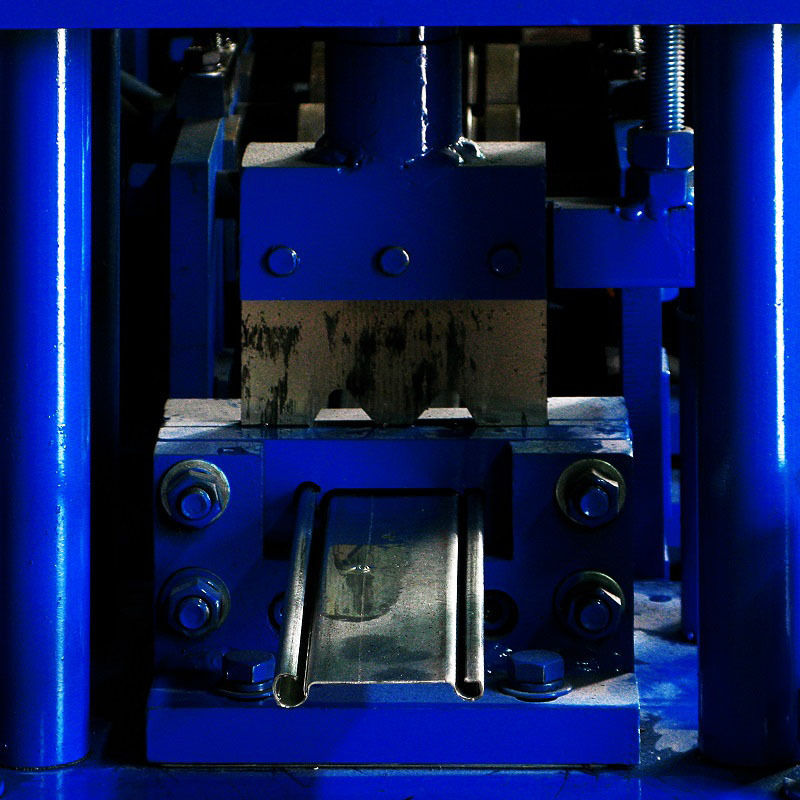

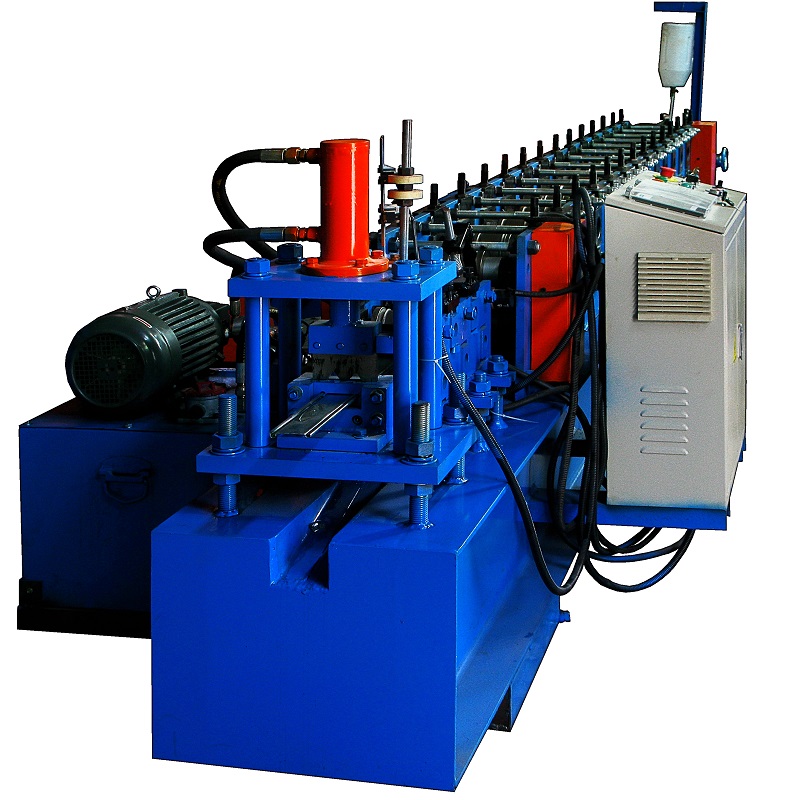

HVAC Fire Damper Blade Roll Forming Machine

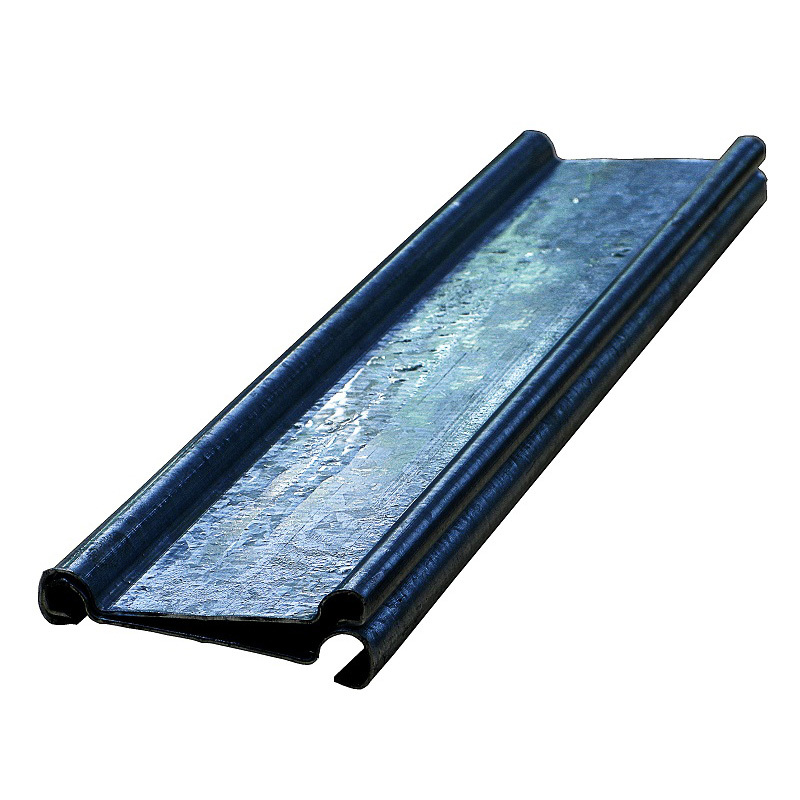

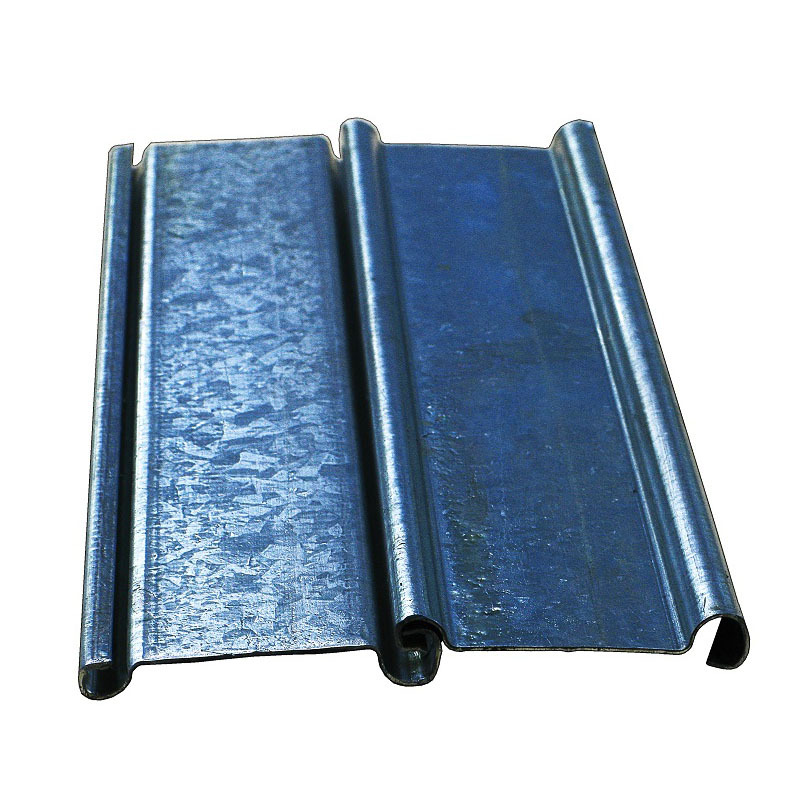

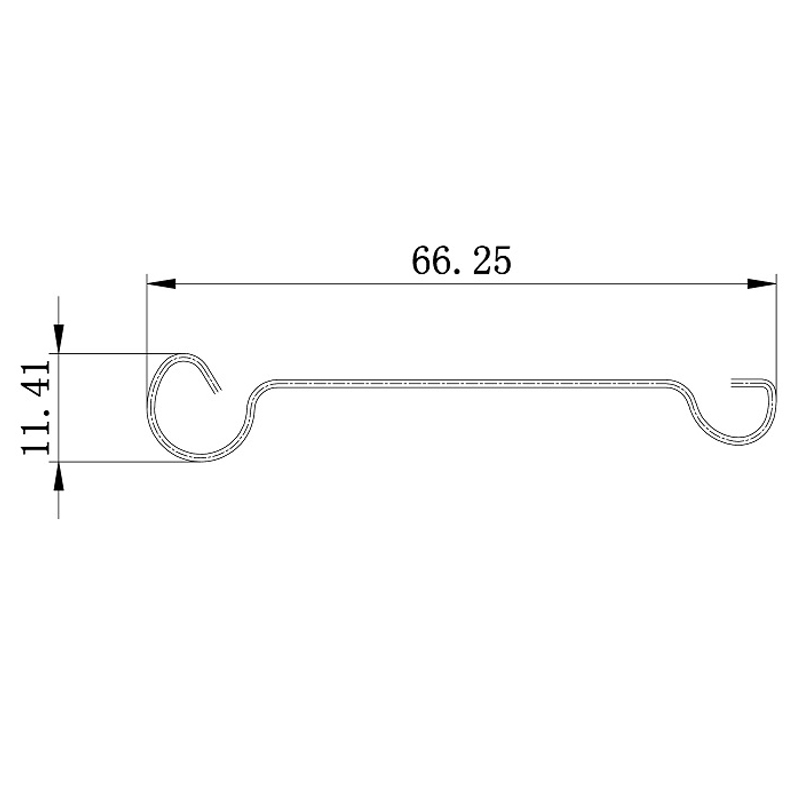

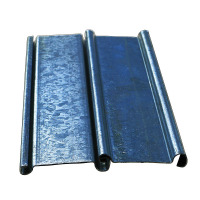

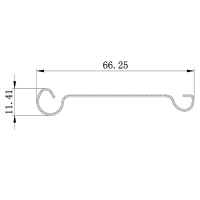

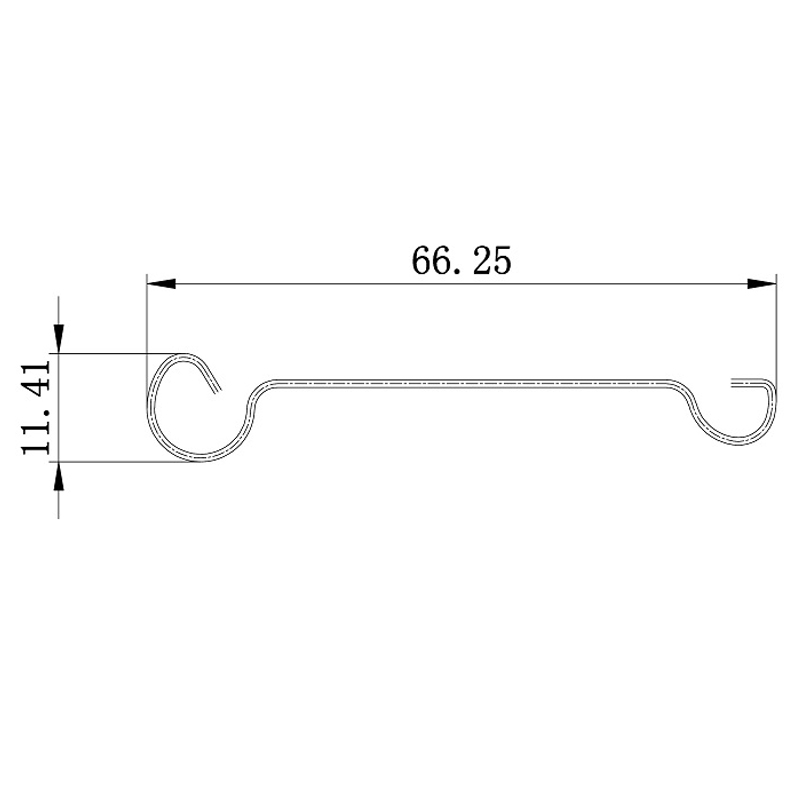

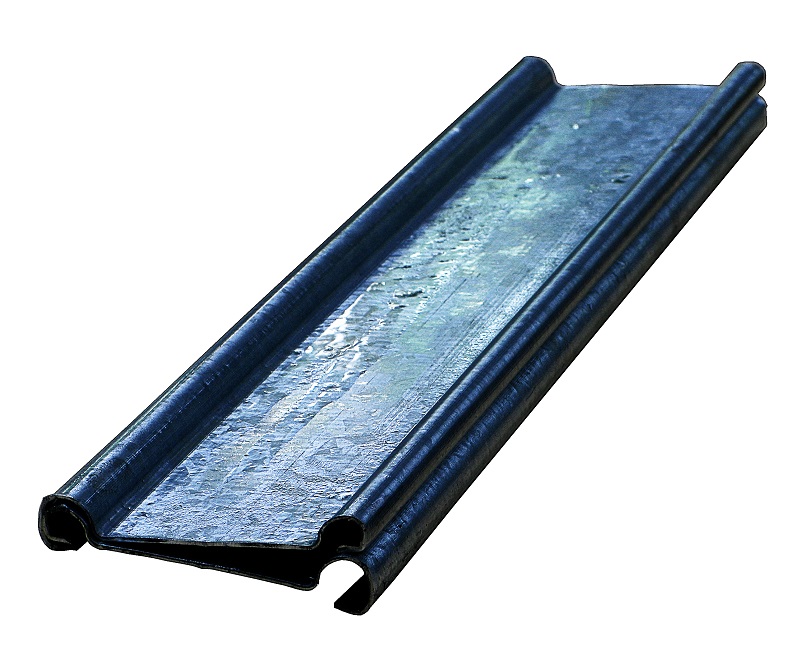

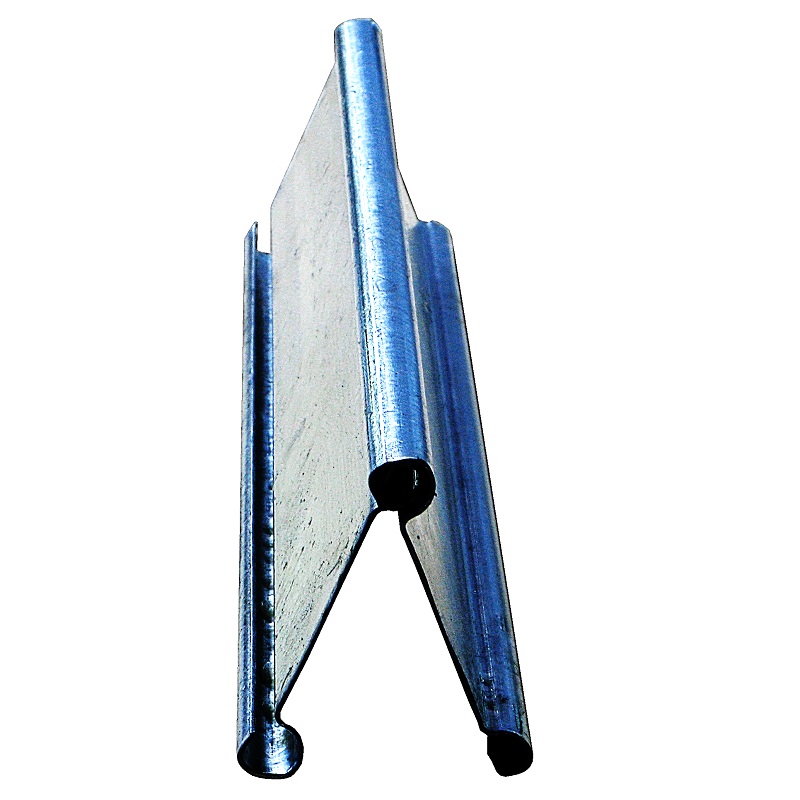

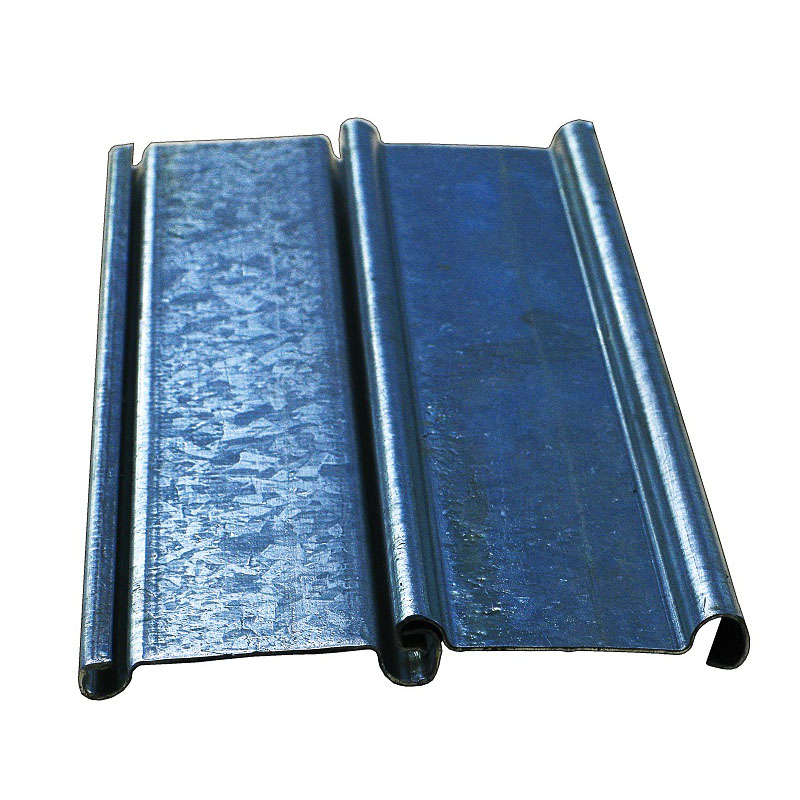

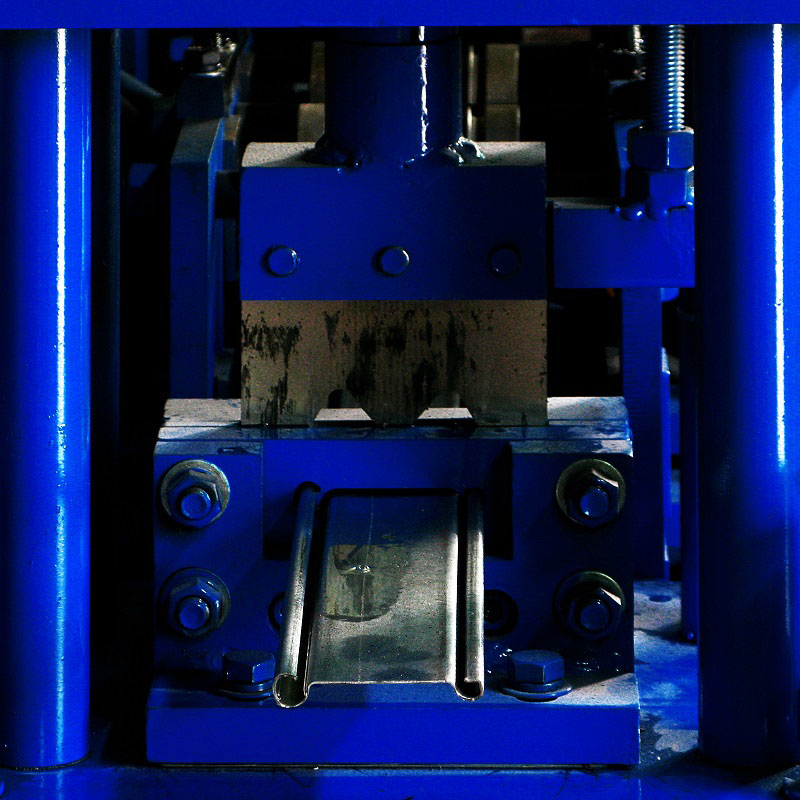

The fire damper blade roll forming machine is a complete production line for manufacture of various shapes of damper blade with or without slotted holes. It is made from light gauge steel thickness from 0.8-1.2mm.The roll formed fire damper blade is a technical profile which can fold and joint together with hands or simple tools.

We could design and produce smoke damper blade roll forming machine too, it is a cost-effective and smart single roll former.The basic technology is same as the roller shutter slat roll forming machine.

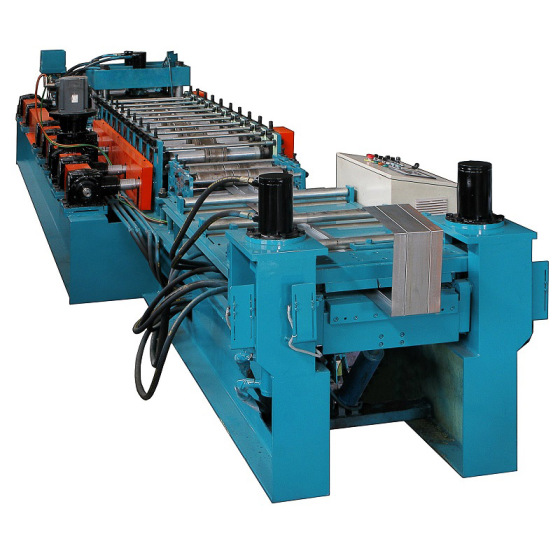

Our fire damper blade forming machine consists of Decoiler, Main Roll Forming Mill, Post Cutter, Hydraulic Station, FLC Control Cabinet, Exiting Rack.

- Meishun

- Xiamen

- 30-50 days

- 100 sets/annual

- Information

HVAC Fire Damper Blade Roll Forming Machine

| Equipment Parameters | |

| Equipment Name: | YX 11-65 Fire Damper Blade Roll Forming Machine |

| Forming Steps: | 14 groups roller |

| Equipment Components: | |

| Equipment Size (L x W x H) | 5.5m x 1.5m x 1.2m |

| Main Motor Power | 5.5KW |

| Hydraulic Motor Power | 3KW |

| Equipment Total Weight | Approx. 4 tons |

| Blank Material Type | Galvanized Steel |

| Material Thickness | 0.8-1.2mm |

| Material Width | 95mm |

Please feel free contact us and sending your profile drawing & parameters. Our cost effective and high performing roll forming machine will satisfy well your requirement.

Meishun Machinery provide reliable machines in a wide range of industries, construction and other fields. We will continue to research, develop and produce high-performance, energy-saving, compact and environment-friendly roll forming machines to better adapt to environmental and social development and contribute to your production.

Through the integration of innovation and energy-saving technology, more efficient, reliable, safe and lasting operation can be realized.

We choose the raw materials with reliable quality to ensure the long-term and stable operation of the machine.